PVC (Polyvinyl Chloride) coated water hose is widely used in agricultural, industrial, and household irrigation. By coating a fabric substrate with a layer of PVC resin, the hose achieves superior performance. This article will detail the advantages of PVC coated water hoses.

PVC coated water hoses have exceptionally high wear resistance, allowing them to be used in complex terrains and harsh environments. Compared to traditional rubber hoses, PVC coated water hoses are less prone to wear during dragging, leading to a longer service life, reduced replacement frequency, and lower usage costs.

PVC material has excellent weather resistance, capable of withstanding UV rays, oxidation, and various chemical corrosions. Whether in high or low-temperature environments, PVC coated water hoses maintain good flexibility and strength, resisting aging and cracking, ensuring long-term performance.

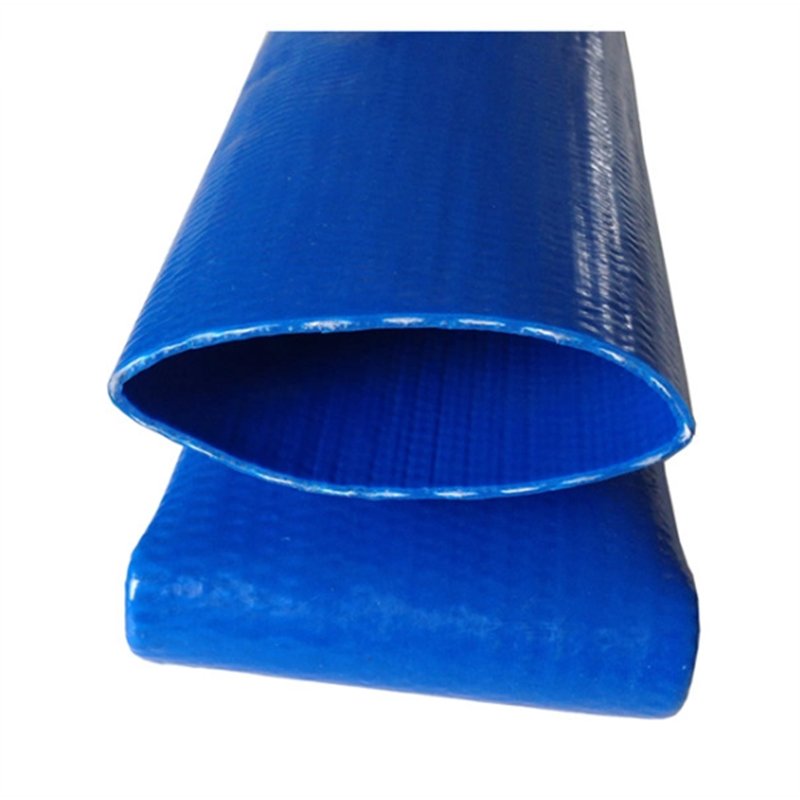

PVC coated water hoses are relatively lightweight, making them easy to carry and use. Their soft material allows the hose to be coiled into a small volume for storage, saving space. Additionally, the lightweight nature of PVC coated water hoses reduces transportation costs, facilitating flexible use in different scenarios.

PVC coated water hoses have high pressure resistance, able to withstand significant water pressure without deforming or bursting. This makes them perform excellently in high-pressure water systems, ensuring stable and efficient water flow, meeting the needs of applications requiring large water volumes such as agricultural irrigation and firefighting.

PVC is an eco-friendly and non-toxic material, free from harmful substances during production and without releasing toxic gases during use, making it safe for the environment and humans. Additionally, PVC material can be recycled, reducing resource waste and aligning with sustainable development principles.